Brayden DeVito

Spring-Loaded Holding Fixture

3D Model / Tooling Concept / Manufacturing Pictures

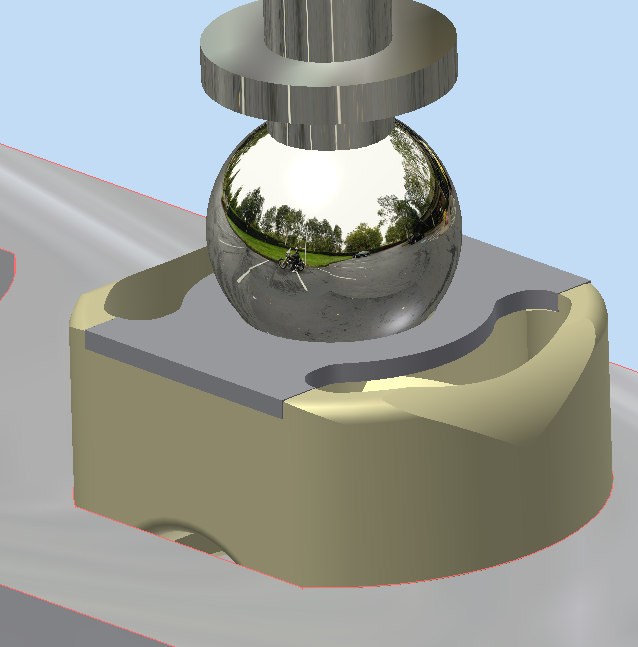

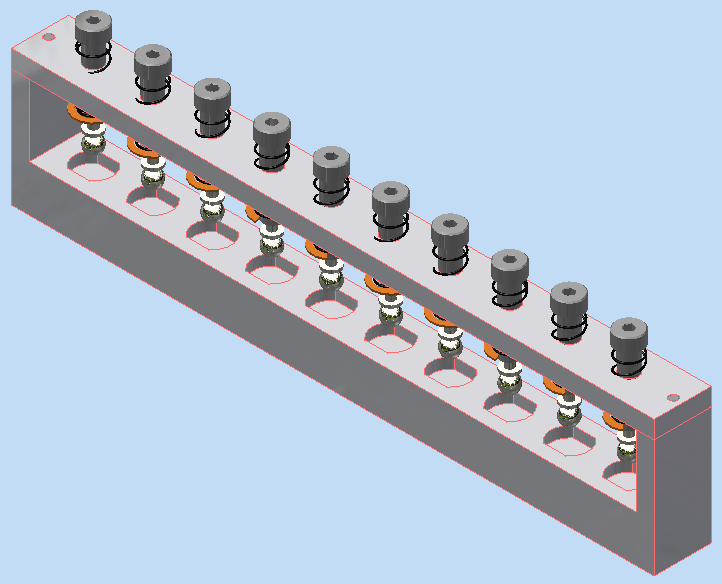

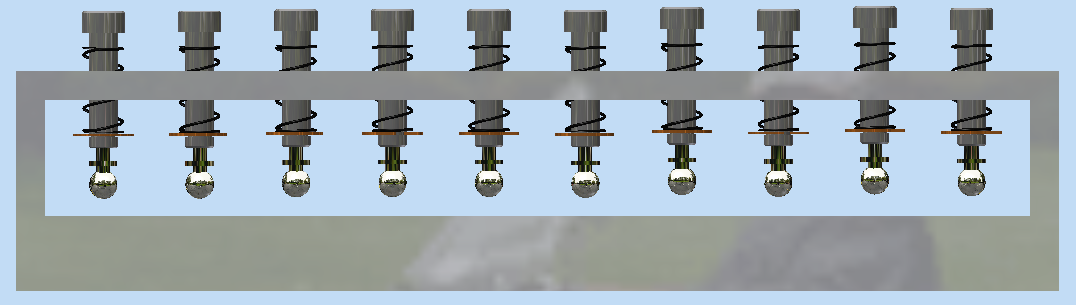

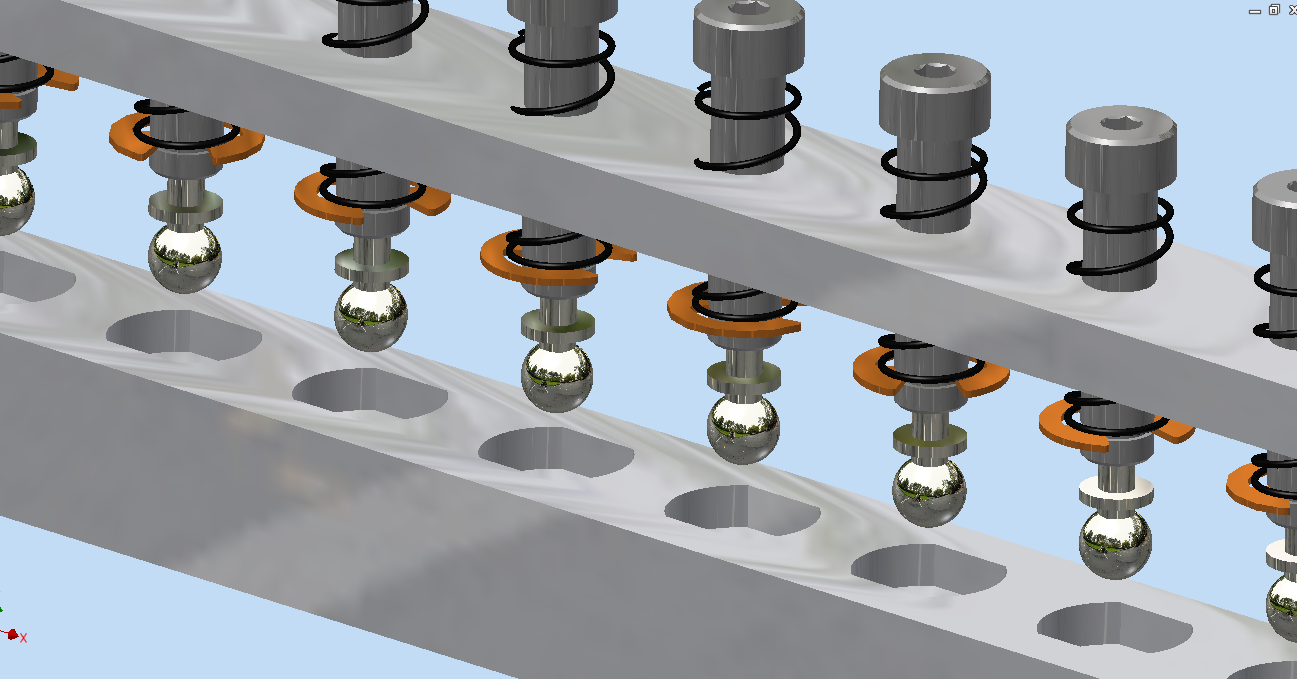

For this project, the customer was having difficulties laser welding their medical hardware together successfully. On the existing tooling design, the parts were held loosely, not fulfilling the concentricity callout of the finished product; Thus resulting in rejections, and structural failures. The newly designed tooling holds 10 pieces, and with the addition of the tooling ball, the parts are held on a similar centerline, and eliminated the issue of the concentricity problems. As well as solving the concentricity problems, the spring loaded design drasticly helps with the welding process as the parts are held together much more firmly.

– Isometric View

– Front View

– Closeup