Brayden DeVito

Micro Analysis

Cross Sectional Weld Joint Analysis

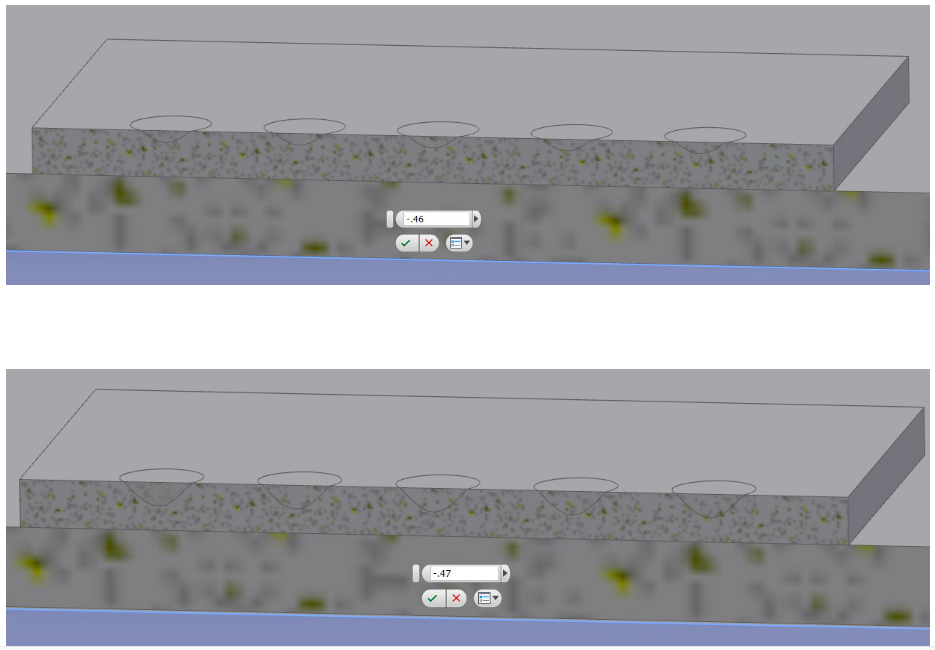

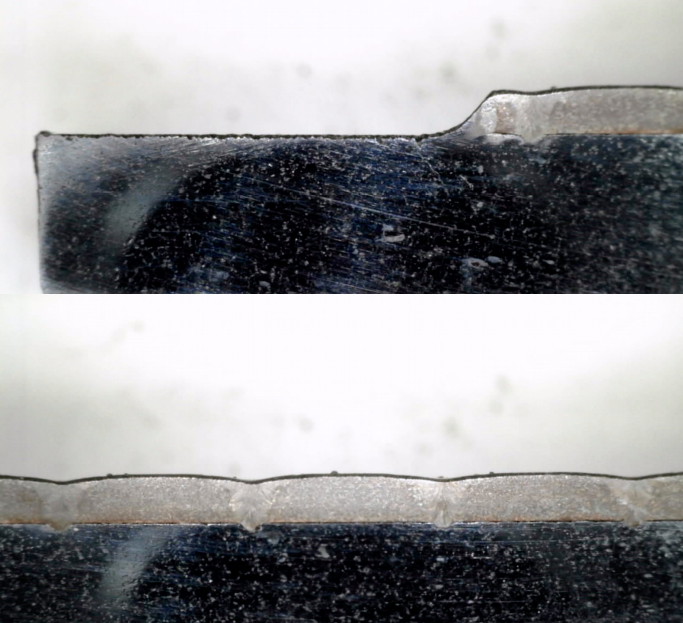

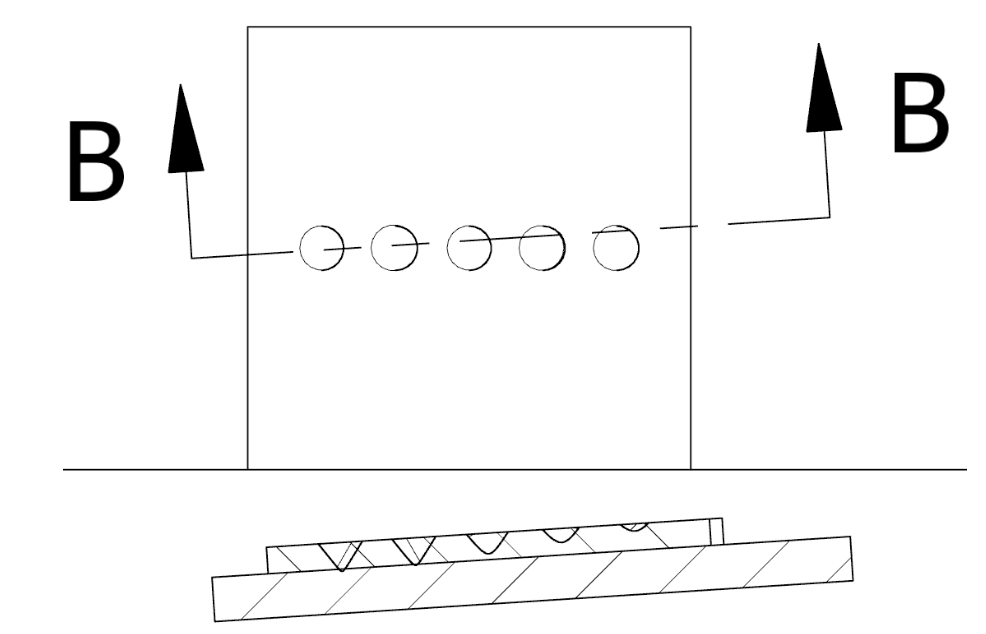

A fairly common practice that I have become proficient at is micro-analysis of the internal structure of a weld joint. The part is cross sectionally cut, polished to a near mirror finish, and a reagent is applied, forcing the difference in weld metal and parent metal to pop out, and become easily visible. After the part is etched, it is scrutinously looked at under high powered microscopes to check for a various host of issues that can cause a weld to be labeled as "nonconformant." a few rejectable qualities for internal weld quality are such things as cracking, porosity, heat affected zone, undercut/underfill. The report below shows a sample that has been sectioned, polished, and etched before being evaluated.

– Sample View

– Sample View

– Sample View

– Sample View